![]()

Advanced Cam Unit Processing Breakthrough Innovation

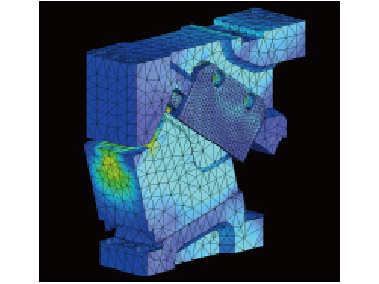

Reliability by increased rigidity and durability testing

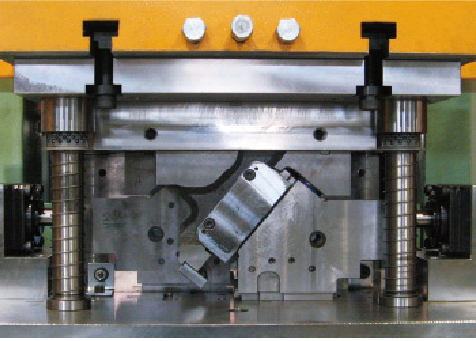

Distortion has been reduced by 40% compared to the conventional cam units by reviewing the basic design and optimizing the shape by using CAE. Rigidity has been greatly increased without increasing the size or changing the material. In addition, an impact absorbing structure suitable for servo press machines has been adopted. This allows the impact force generated when the press ascends to be controlled. Durability laboratory tests have been repeatedly conducted in our servo press machine to ensure safety and reliability.

Durability test with a servo press machine

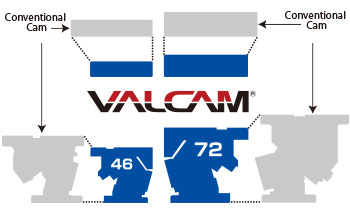

Reduction in size for space saving

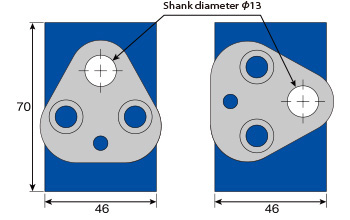

46mm is the smallest in its class and this has been determined by minimizing the cam width so that a retainer having a shank diameter of h 13mm can be installed. The processing of adjacent cam piercing and installation in tight spaces are easily obtained. Even though the overall length of the cam is shortened, the working force, return force and stroke are equal or better in performance than the conventional cam units. This substantially reduces the area occupied by the cam unit in a die, thus downsizing the die and reducing the number of processes.

Cam width of 46mm has been achieved.

Compared to the conventional cam, the entire cam unit volume has been reduced by reducing the camwidth and overall length.

Prevention of sticking with increased return force

Prevention of sticking with increased return force

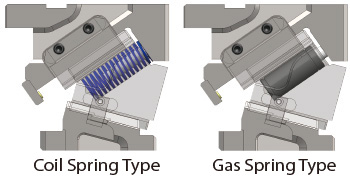

To prevent cam from sticking on a panel, which is a problem in High Strength Steel processing, the return force has been increased by 33% compared to the conventional cam units in the coil spring type. In the gas spring type, the return force has been strengthened 10% more than the maximum working force. Moreover, coil and gas spring mounting configurations are interchangeable allowing for increased return force when required.

Improvement in flexibility of die design and ease of use

For up to 72mm width, two types of strokes (short and long) can be set. The suitable stroke for an application can be selected, pad design can be made easier and improve die design flexibility. Moreover, considering various types of working conditions, a well-balanced design has been realized using CAD/CAE. While overall capability has been improved, the design has been optimized in areas where forces are not applied, resulting in lighter weight.

Optimized cam unit selection that corresponds to various processes

Cam units for light to heavy loads are available with the same envelope and mounting configuration.

The cam units are suitable for a wide variety of panel materials including mild steel, aluminum, and high strength steel. The optimum cam unit for processing conditions such as working force and return force can be selected from the wide-ranging of cam units offered. Furthermore, when the working force or return force changes, he cam units can easily be changed thanks to VALCAM interchangeability.

The new widths cover larger areas. Piercing of multiple holes or trimming and piercing can be done at the same time.

Please click the link below to see cam detail.

•Click Here for Technical Overview/Cam Replacement Parts

| Grade | Cam Width [mm] | Working Force[kN(tonf)] | Stroke | Angle (5-degree increment) |

Catalog No. |

Spring Type | Features | Application | |

|---|---|---|---|---|---|---|---|---|---|

| 1,000,000 strokes |

300,000 strokes |

||||||||

|

◯

|

46 | 22.1 (2.2) |

29.4 (3.0) |

Short | 0°~80° | VACWS46 |

|

Cast iron sliding

Compact size

|

Pierce |

| Long | 0°~50° | VACWL46 | |||||||

| 58 | 27.9 (2.8) |

37.2 (3.8) |

Short | 0°~80° | VACWS58 | ||||

| Long | 0°~50° | VACWL58 | |||||||

|

●

|

46 | 22.1 (2.2) |

29.4 (3.0) |

Short | 0°~80° | VACSS46 |

|

Cost iron sliding

|

Pierce |

| Long | 0°~50° | VACSL46 | |||||||

| 58 | 27.9 (2.8) |

37.2 (3.8) |

Short | 0°~80° | VACSS58 | ||||

| Long | 0°~50° | VACSL58 | |||||||

| 72 | 36.8 (3.7) |

49.0 (5.0) |

Short | 0°~80° | VACSS72 | ||||

| Long | 0°~50° | VACSL72 | |||||||

|

●

|

46 | 30.9 (3.1) |

41.2 (4.2) |

Short | 0°~80° | VACYS46 |

|

Copper alloy slinding

Uneven load

|

Pierce Trim ※Flange |

| Long | 0°~50° | VACYL46 | |||||||

| 58 | 42.6 (4.3) |

56.8 (5.8) |

Short | 0°~80° | VACYS58 | ||||

| Long | 0°~50° | VACYL58 | |||||||

| 72 | 60.3 (6.1) |

80.4 (8.2) |

Short | 0°~80° | VACYS72 | ||||

| Long | 0°~50° | VACYL72 | |||||||

| 100 | 86.7 (8.8) |

103.9 (10.6) |

Long | 0°~70° | VACYL100 | ||||

| 140 | 112.8 (11.5) |

135.3 (13.8) |

Long | 0°~70° | VACYL140 | ||||

| 200 | 141.1 (14.4) |

164.6 (16.8) |

Long | 0°~70° | VACYL200 | ||||

| 300 | 225.4 (23.0) |

254.8 (26.0) |

Long | 0°~70° | VACYL300 | ||||

| 400 | 269.5 (27.5) |

294.0 (30.0) |

Long | 0°~70° | VACYL400 | ||||

|

●

|

46 | 36.8 (3.7) |

40.9 (5.0) |

Short | 0°~80° | VACPS46 |

|

Copper alloy sliding

Uneven load

|

Trim ※Flange |

| Long | 0°~50° | VACPL46 | |||||||

| 58 | 51.5 (5.2) |

68.6 (7.0) |

Short | 0°~80° | VACPS58 | ||||

| Long | 0°~50° | VACPL58 | |||||||

| 72 | 67.7 (6.9) |

90.2 (9.2) |

Short | 0°~80° | VACPS72 | ||||

| Long | 0°~50° | VACPL72 | |||||||

| 100 | 116.1 (11.8) |

139.2 (14.2) |

Long | 0°~70° | VACPL100 | ||||

| 140 | 159.3 (16.3) |

191.1 (19.5) |

Long | 0°~70° | VACPL140 | ||||

| 200 | 197.6 (20.1) |

230.5 (23.5) |

Long | 0°~70° | VACPL200 | ||||

| 300 | 315.6 (30.2) |

356.7 (36.4) |

Long | 0°~70° | VACPL300 | ||||

| 400 | 377.3 (38.5) |

411.6 (42.0) |

Long | 0°~70° | VACPL400 | ||||

|

●

|

46 | 49.0 (5.0) |

49.0 (5.0) |

Short | 0°~80° | VACBS46 |

|

Uneven load

|

Pierce Trim ※Flange |

| Long | 0°~50° | VACBL46 | |||||||

| 58 | 68.6 (7.0) |

68.6 (7.0) |

Short | 0°~80° | VACBS58 | ||||

| Long | 0°~50° | VACBL58 | |||||||

| 72 | 90.2 (9.2) |

90.2 (9.2) |

Short | 0°~80° | VACBS72 | ||||

| Long | 0°~50° | VACBL72 | |||||||

*CENTER LOAD working forces

Click Here for Technical Overview

Some models are not

manufactured by Sankyo Thailand.

In detail, please contact info@th.sankyo-oilless.com

Copyright © 2020 Sankyo Oilless Industry, Inc. All Rights Reserved.